In addition to storing memorable photos, you can also arrange cards or stickers of your favorite characters. Albums are for preserving precious memories, so we want to make something individualized and special. At Sekisei Kosan, we have a skillful team to do just that.

When visiting the Tachikawa Factory, you can see the deep bonds between workers, each of whom is dedicated to the album production process.

Technique to make tailored album mounts

Sekisei Kosan’s Tachikawa Plant manufactures pasteboards, a type of album mount paper that allows photos to be freely pasted and removed from the adhesive material.

The machines at this factory were developed specifically for producing album mounts and we have been creating great products for 40 years. It is precisely because of this machine that we can respond to specific requests from the thickness and size of the paper, the degree of adhesiveness, color, size, and even patterns. We tailor to the customer’s needs and preferences.

It’s not just the machines at work – dedicated factory staff with years of profession carefully assess the finished product.

The reason for this commitment to quality is rooted in the will of the company’s founder, Seiichiro Nishikawa. When he founded the company in 1932, a time when Japan did not have files for sorting documents as functionally as today, he wanted to facilitate business smoother with convenient stationery and boost the postwar Japanese economy. Instead of just relying on other companies to gather material, he wanted to produce products with a commitment to quality by tailoring to their business needs and being involved in the production process. This spirit lives on today.

Beautifully handcrafted album covers

The cover of an album is everything. We handcraft album covers carefully by attaching a core of paperboard to the cover and folding it around the perimeter.

All of our staff members are skilled artisans. They work together in front of the conveyor belt with perfect flow and admirable teamwork.

Foil stamping, which gives the album cover a sense of luxury design, also requires a certain skill. A foil-stamping machine can create all kinds of designs, and the pressure is slightly adjusted according to the thickness and material of the paper. Gold and silver foils are used, and beautiful covers are created one after another, one by one, with careful attention to the position and force of each foil point, and yet without wasting time.

How it comes together

So, with many hands working together and with the help of machines, an album is complete. The finished product is checked to ensure that the corners are clean and that there is no misalignment or sagging. Only quality products that meet the standards at Sekisei Kosan are shipped.

Approximately 3,000 albums are manufactured at this factory each day. In addition to products sold in general merchandise stores, the factory also produces special mounts for photographers and photo studios. To meet a wide range of needs, each of these products is made with care and without cutting corners.

Sharing the joy of looking at photos in photo albums to the next generation

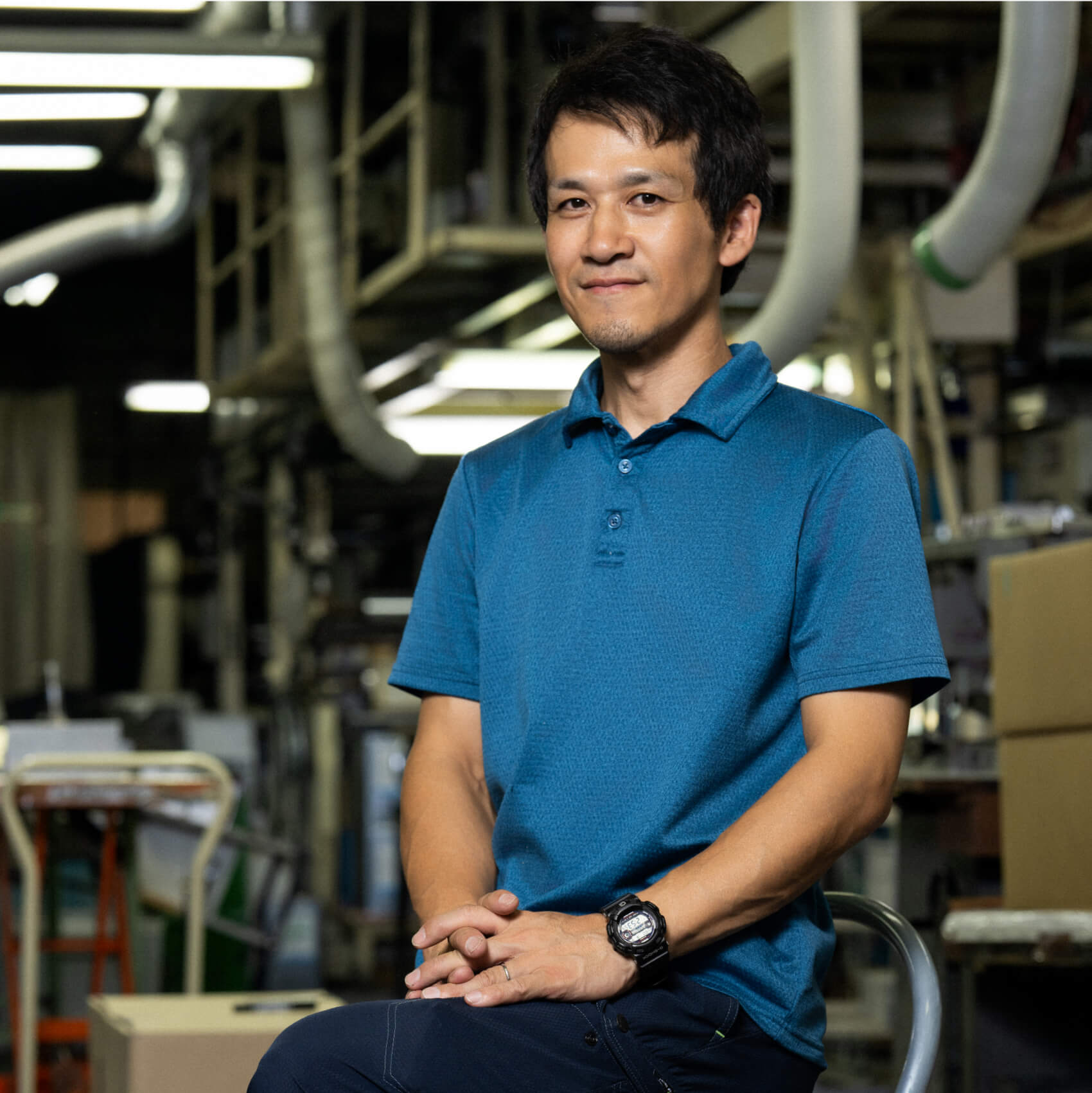

Ken Senbokuya, one of the longtime workers at the factory, is as passionate about photo album production as anyone else, and while working to create a comfortable working environment, he is also looking to develop new products.

--What kind of work do you usually do?

Above all, I am in charge of making a comfortable work environment. I also do “pre-processing,” such as cutting the cardboard that will be used as the core of the cover.

--Why did you choose this job?

More than 20 years ago, I quit my previous company when I got married. At that time, my wife was pregnant, and we were expecting our first child, so I took a lot of pictures. I started to put those photos in an album. I don’t particularly like being in front of cameras, and never had much to do with photography before in my life, but I found this job when I developed a newfound appreciation for photos and albums. Life is funny like that. I got along very well with the company’s CEO, and I became a part of the company.

--What do you find most rewarding about your job?

We use machines, but most of our work is handmade. It is fun to be able to craft rather than just make a large amount of products by machine, and sometimes, hands do a better job at creating exactly what we are imagining rather than machines. That said, there are things that only this machine can do, and its techniques are unique to Sekisei Kosan, so we want to take advantage of that and create more products.

--Is there anything you pay attention to in your work?

Paper can be affected by humidity, so I am very careful about handling paper. If the humidity in a room becomes too high, the paper will ripple quickly. Dryness during the winter is also a great enemy. If the paper goes bad, no matter how much we clean up the processing afterward, it will not be a good product. I think this is something I have yet to catch up with my experience, no matter how many years I have been doing this.

--What are your goals for the future?

Albums are mainly used for pasting photos, but recently, they have been used to hold cards. I hope that in the future, we will be able to open up new avenues, such as changing the materials used. Recently, small-size albums have become popular, and I think many people are filling them with photos of memories with friends and giving them as gifts. I want to respond to that trend and create cute, thoughtful products that customers will treasure.

Photo: Alex Abian, Kim Marcelo

RECOMMENDED ARTICLES

-

Instant photo albums preserve not only photos but also the feelings from the moment they were taken.

At SEKISEIKOHSAN, we manufacture albums for collecting photos taken with instant cameras like Instax, Polaroid…

-

Sustainable Materials for Stationery

Making Eco-friendly ChoicesAt SEKISEIKOHSAN, we are committed to developing products that are both environmentally and socially responsible by exploring new, sustainable materials.